Authors

-

John Pabon

Former Manager, BSR

When you think about industry in China, what images come to mind?

Most imagine gigantic factories, with lines of workers churning out low-cost goods bound for markets abroad. This China pulls from the ground with disregard for environmental implications. It pushes workers to the limit, knowing a steady supply of replacements wait just outside the factory gates.

This may have been the case in the past, but not so anymore.

Chinese industry is entering a new era in which optimization of resources, labor, and cost is critical. A slowing economy, as well as an uncertain geopolitical environment, means the government must find new ways to stay globally competitive.

To do this, China is positioning itself to become more domestically self-sufficient, service-oriented, and competitive than ever before. BSR’s latest working paper, “Optimizing Chinese Industry in the Age of Automation” explores the impact these shifts will have on global businesses and their supply chains. To stay on top of these changes and ensure sustainable business practices, businesses should begin to rethink their supplier relationships and support economic inclusion.

China’s economic shift is being accelerated by rising labor costs, changing policy, and the ever-present specter of automation. For instance, labor costs for the average Chinese worker have increased 15 percent year on year since 2000. When factoring in productivity, Chinese wages are only 4 percent lower than those in the United States. This means that businesses should no longer think of China as a market for cheap production of goods.

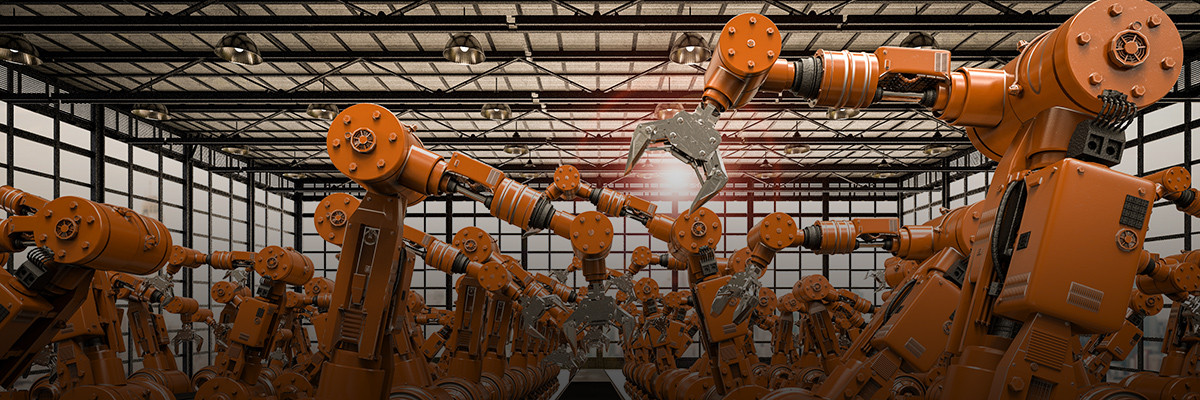

Beyond that, policy responses, like the Made in China 2025 plan, aim to bolster productivity, developing domestic manufacturing sophistication that can overtake Germany, Japan, and the United States. And President Xi Jinping’s proclamation of a “robot revolution” will free up billions of renminbi for technology upgrades and industrial robotics. It also starts to address labor costs and shortages. In one startling example, the manufacturing hub of Guangdong aims to automate 80 percent of its factories by 2020.

These shifts will require major changes to the way global businesses operate in China. To that end, the paper also provides recommendations to prepare the workforce of today for the workplace of tomorrow through new approaches to supplier relationships and a focus on an inclusive economy.

Supporting Supplier Relationships

As China moves away from low-end manufacturing, business can play a positive role in shaping the country’s future supply chain. This will be mutually beneficial for both the government and a company. Accomplishing such goals will require investment, engagement, and preparation.

- Invest: Companies should not assume that internal leadership or supply chain partners know about the changing landscape. They should invest in knowledge-sharing that builds management capacity to handle present-day shifts.

- Engage: Companies should have an open dialogue with supply chain partners to get on the same page about what the future holds. They should start by asking: What will it take to stay competitive over the next decade?

- Prepare: The changes happening today will affect different industries in different ways. Those well on their automation journey, such as automotive companies, can share learnings with industries yet to experience change. As they onboard machines, leaders at companies in heavy manufacturing and the information and communications technology sector should consider the risks and labor impacts that automation brings.

Supporting Economic Inclusion

It’s not only the supply chain landscape that is changing. Optimization of the labor force will mean fewer low-skill jobs, higher competition, and a shift in job knowledge requirements. By preparing well today, business can fulfill a moral imperative in supporting economic inclusion among the Chinese workforce. This preparation is twofold.

- Upgrade skills: Companies should assess whether workers have what it takes to be competitive in the workplace of tomorrow. Streamlined operations mean fewer workers accomplishing multiple tasks, so learning and development mechanisms should support a diversification of skills. These mechanisms should also make use of technology to create mobile, accessible, adaptable, and meaningful content.

- Reimagine mobility: Traditional mobility is often seen as a ladder. Reimagined mobility is like a roundabout, with many paths to choose. Some workers may choose to stay within a company. Others may choose to take newfound skills and create their own organization. Regardless, business should consider mobility as an investment in the future competitiveness of a worker, rather than a cost to the company that the worker must pay back through loyalty. With millions at risk of losing jobs in this changing landscape, business can help ensure a painless transition for displaced workers.

At the BSR Conference 2016, John L. Thornton, Executive Chairman of Barrick Gold Corporation, noted that “every person knows far, far less than they should about China.” Given dynamic changes in the country, now is the time to brush up. This isn’t an exercise in multicultural awareness, however. With China squarely at the center of global supply chains, any changes there resonate throughout the world. As shifts in policy, labor, and use of automation occur, is your business ready for an inevitable future where China is no longer simply the world’s factory, but an optimized market of its own?

Topics

Let’s talk about how BSR can help you to transform your business and achieve your sustainability goals.